|

|

| Home | About Us | Product | Know How | Contact Us | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

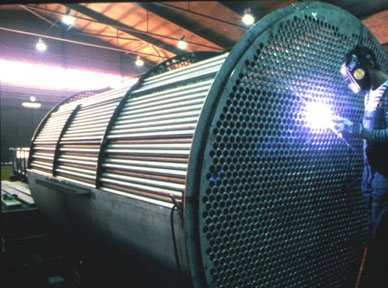

ASTM A179/ASME SA179 Standard Specification for Seamless Cold-Drawn Low-Carbon Steel Heat-Exchanger and Condenser Tubes |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Standard: ASTM A179, ASME SA179 Equivalent Standards: DIN 17175, BS 3602 Part I, NF A 49-212, NBR 5583, EN 10216-1, EN 10216-2, GB 3087, JIS G3461 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Material: SA179 Equivalent Material: 1010, CFS 360, St35.8, P235TR1, P235TR2, P235GH, 10#, STB340, 0.1-0.15C |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Chemistry Composition | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Mechanical Properties | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Outside Diameter & Tolerance | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Wall thickness & Tolerance | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ASTM A179 (SA179) standard specification covers seamless cold drawn low carbon steel pipe, for tubular heat exchanger, condensers and other similar heat transfer equipment. The ASTM A179 tube covers the OD from 1/8" to 3", which is 3.2mm to 76.2mm. Other diameters and thickness smaller than the specified sizes also applicable to this standard, but mechanical properties is not applicable for the size smaller than 1/8" and 3.2mm, or thickness smaller than 0.015 inch and 0.4mm. In most cases, ASTM A179 replaces ASTM A178 in China. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Manufacture: tubes shall be made by the seamless process and shall be cold drawn. Heat Treatment: tubes shall be heat treated after the final cold draw pass at a temperature of 1200°F [650°C] or higher. Delivery Condition: pickling, nitrogen protection surface or bright annealing. Some south korea mills buy mother tubes and only do bright annealing heat treatment in their country, because pickling is a must, but many countries don't allow this process. And nitrogen protection is now popular in China, the surface is similar bright apperance, but low cost. Inspection & Test: chemistry composition analysis, tensile test, flattening test, flaring test, hardness test, NDT, surface inspection and dimension check. Optional Test: flange test. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Some sizes requested by clients | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Length: 4907mm; 5800mm; 6000mm; 6096mm; 7315mm; 9000mm; 11800mm; 13000mm; 15000mm and so on. Max length: 30000mm, U bending can be offered, also see the fin tubes. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Keyword: Cold Drawing - Condenser Tubes - Condensers - Drawing - Heat Exchanger Tubes - Heat Exchangers - Low-Carbon And Mild Steel - Low-Carbon Steel - Seamless Pipes And Tubes - Seamless Steel Tubes - Steel Tubes - Tubular Products - High Flux Tube - High Flux Tubing - Heat Exchanger Steel Tubing - Heat Exchanger Tubing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Home | About Us | Product | Know How | Contact Us | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||